From Ocean Awareness to Sustainable Innovation – Our Commitment to a Greener Future

Ocean pollution is destroying ecosystems at an alarming pace. Plastic waste floats on the surface, and marine life is losing its home.

In the face of this crisis, protecting the environment is our responsibility.

However, change is within our reach.

Since our founding, we have embraced sustainability as our core belief, using innovative green technologies and eco-friendly manufacturing to help safeguard the planet.To ease environmental stress and protect our oceans and ecosystems, we start at the source — our production process. By adopting advanced, intelligent, and eco-friendly equipment, we improve efficiency while embedding sustainability into every stage of manufacturing.

Solar photovoltaic systems

- An investment of 5 million yuan was made, and more than 2,300 photovoltaic panels were adopted in total.

- Installation Area: Solar Photovoltaic System (12,000 square meters)

- Annual electricity savings: 8 million kWh.

- Annual reduction: 7,976 tons of carbon dioxide emissions. Equivalent to planting 438,400 trees annually.

SULLAIR( American )

Centrifuge Equipment System

- A total investment of 3 million yuan was made to adopt the current international energy-saving and efficient centrifuge equipment. The dew point can reach above minus 50 degrees, achieving oil-free emission and zero gas consumption energy-saving dehumidification conditions. The specific power is 30% lower than that of traditional screw machines. Based on the annual gas production, it saves about 30% energy compared with ordinary models

Intelligent Temperature and Pressure Control

Waterway Control System

- The total investment is approximately 10 million.

- The intelligent water system, fully known as the intelligent constant temperature and pressure circulating cooling water system, is a high-tech energy-saving water supply device integrating machinery and electronics. It applies the advanced PLC logic control technology, combining frequency converters with water pumps.

- Adopting internationally renowned brand screw-type refrigeration system equipment ensures stable production processes and product quality, reduces the defective rate, and increases production efficiency by more than 10%-20% compared to traditional ordinary control systems.

Automatic Conveyor Central Feeding System

Mixing System

- The injection molding production workshop is equipped with a fully automatic central feeding and mixing system, covering more than 400 injection molding machines. 50% of them use domestic advanced Longfei Ya all-electric injection molding machines.

- The system significantly improves production efficiency and raw material consistency, while reducing manual intervention and energy consumption, providing core guarantee for large-scale stable production.

High-Efficiency Energy-Saving Magnetic Levitation

Air Conditioning System

- The total investment is approximately 12 million.

- By integrating the water system with the air compressor system through thermal energy conversion and recovery, the recycling and utilization of water, gas, and oil energy are realized. After replacing the original screw machine equipment, it can save about 30% of energy consumption in both summer and winter each year.

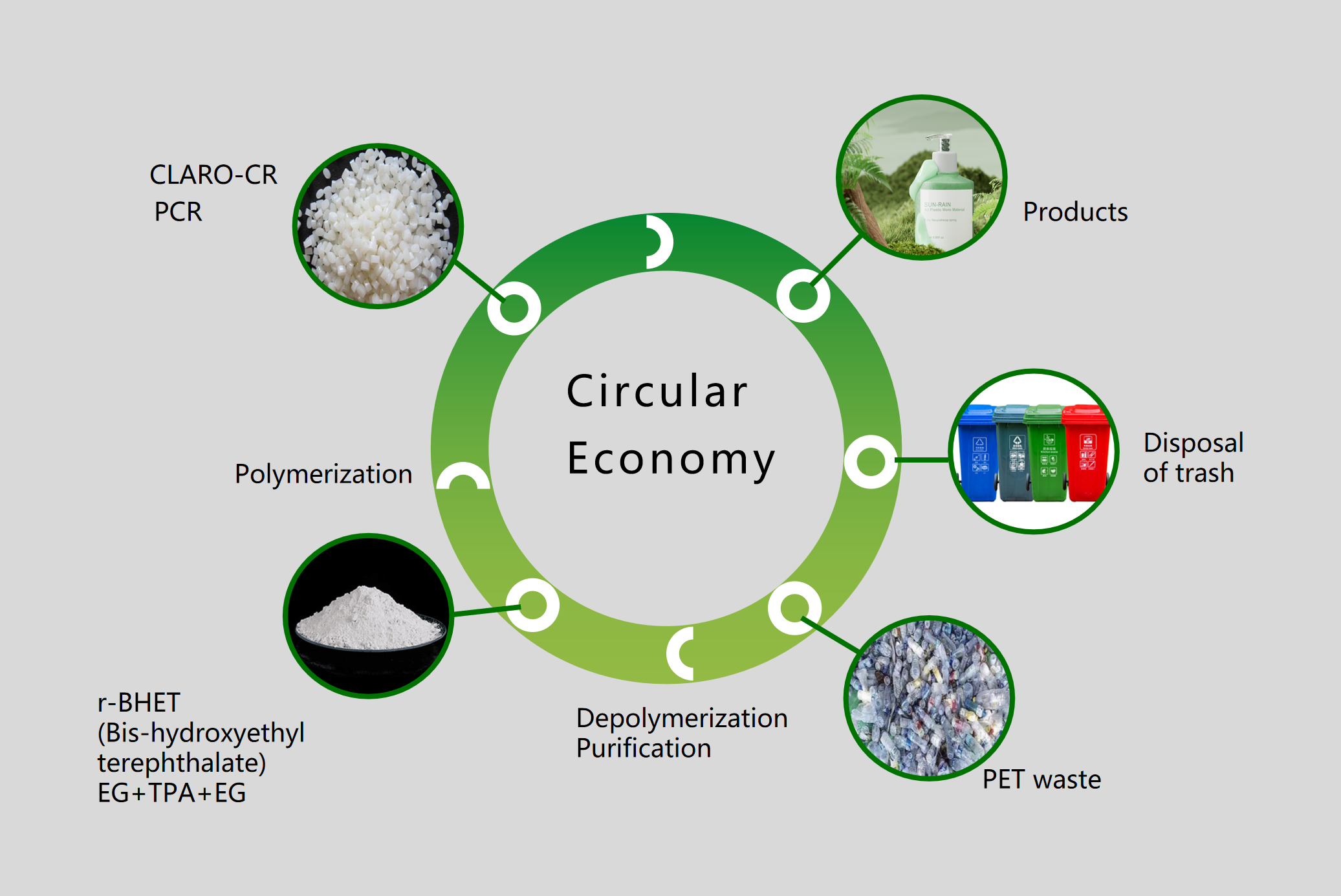

Post-Consumer Recycled

Plastic recycling and regeneration after plastic reduction and low-carbon consumption Usually mixed with raw materials such as PP, PE, PET, etc And then processed for manufacturing new packaging materials Effectively promoting the recycling and utilization of waste plastics

We have only one Earth, and the future of our oceans and nature depends on us all.

Together, let’s innovate and protect, turning every package into a symbol of responsibility and care. Choosing green means choosing a better tomorrow. Let’s make a difference for our planet!