The Common Homeland of Humanity…

countries around the world

have signed up to the act on plastic

but to solve white pollution everyone needs to participate

- In 2010, packaging was redesigned to reduce plastic use by more than 200,000 tons

- In 2021, reduce 50% of plastic packaging use (compared to 2010)

- By 2030, 100% of packaging will be recycled or reused.

- By 2040, the whole chain will achieve net zero greenhouse gas emissions

- Since 2020, the Group has achieved its net zero emissions target, using 100% renewable electricity in the production process and 100% zero industrial watse to landfill

- By 2025, the proportion of PCR material in product packaging of the Group and its brand will reach more than 25%

- By 2030, reduce the use of primary petroleum-based plastic to less than 50%

Founded in 2006 with a vision for the future, we have spent 19 years innovating and expanding in daily skincare packaging, becoming a leading force in the industry.

Certifications for Quality, Safety, and Sustainability

Solar photovoltaic systems

- An investment of 5 million yuan was made, and more than 2,300 photovoltaic panels were adopted in total.

- Installation Area: Solar Photovoltaic System (12,000 square meters)

- Annual electricity savings: 8 million kWh.

- Annual reduction: 7,976 tons of carbon dioxide emissions.

- Equivalent to planting 438,400 trees annually.

Waterway Control System

- The total investment is approximately 10 million .

- The intelligent water system, fully known as the intelligent constant temperature and pressure circulating cooling water system, is a high-tech energy-saving water supply device integrating machinery and electronics. It applies the advanced PLC logic control technology, combining frequency converters with water pumps.

- Adopting internationally renowned brand screw-type refrigeration system equipment ensures stable production processes and product quality, reduces the defective rate, and increases production efficiency by more than 10%-20% compared to traditional ordinary control systems.

Air Conditioning System

- The total investment is approximately 12 million .

- By integrating the water system with the air compressor system through thermal energy conversion and recovery, the recycling and utilization of water, gas, and oil energy are realized. After replacing the original screw machine equipment, it can save about 30% of energy consumption in both summer and winter each year.

Injection Molding Workshop

- The injection molding production workshop is equipped with a fully automatic central feeding and mixing system, covering more than 400 injection molding machines. 50% of them use domestic advanced Longfei Ya all-electric injection molding machines.

- It realizes full-process automation of raw material conveying, proportioning and mixing. Through centralized control and intelligent allocation, the system significantly improves production efficiency and raw material consistency, while reducing manual intervention and energy consumption, providing core guarantee for large-scale stable production.

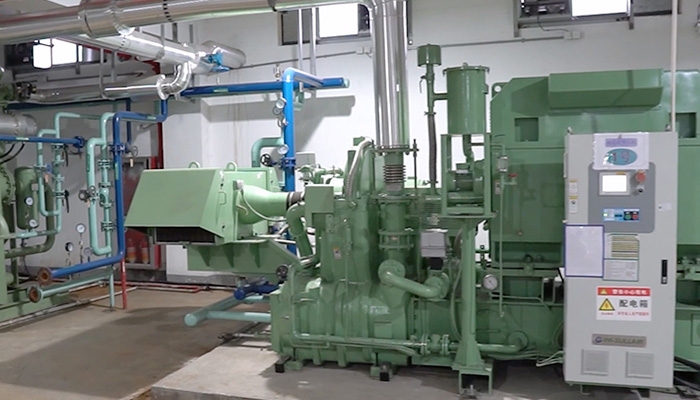

Centrifuge Equipment System

- A total investment of 3 million yuan was made to adopt the current international energy-saving and efficient centrifuge equipment. The dew point can reach above minus 50 degrees, achieving oil-free emission and zero gas consumption energy-saving dehumidification conditions. The specific power is 30% lower than that of traditional screw machines. Based on the annual gas production, it saves about 30% energy compared with ordinary models.

- Taking the production workshop as a unit, intelligent control is realized, and data is collected and analyzed in real time to achieve the goals of stable pressure, ensuring production operations, and energy consumption analysis and control.

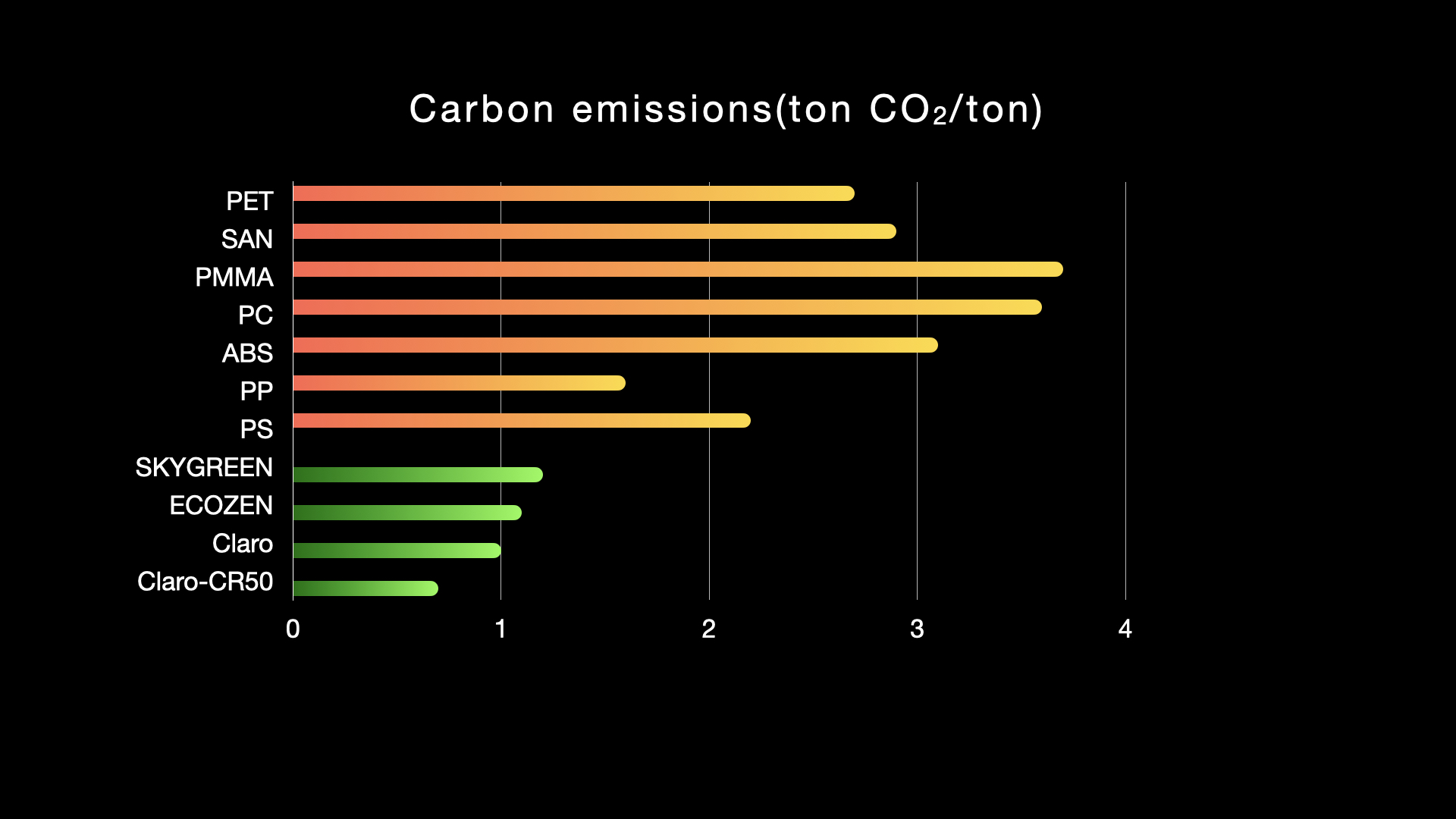

Application of Environmentally Friendly Materials

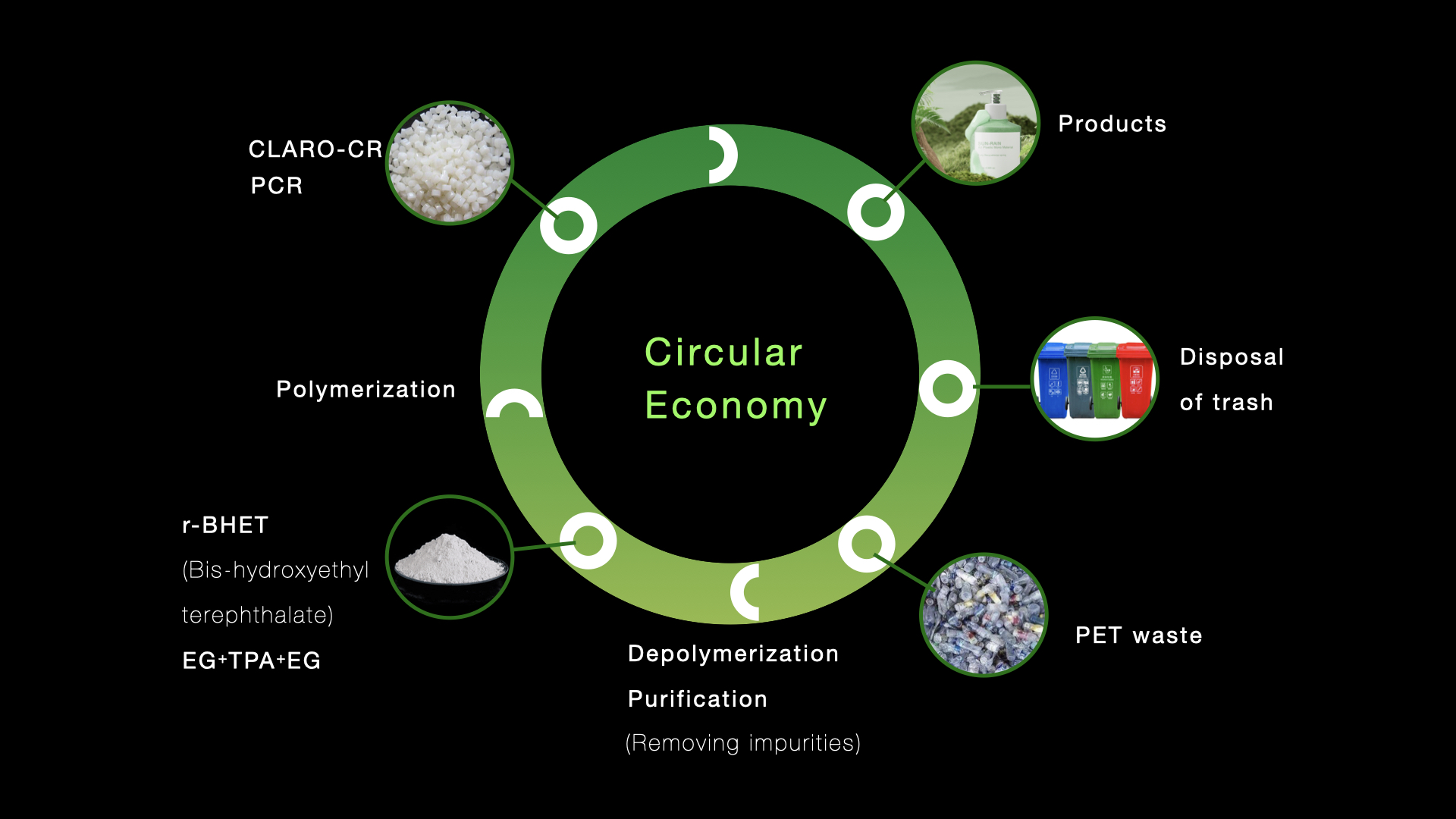

Post-Consumer Recycled

Post-consumer plastic raecycling refers to the process of regenerating waste plastics, which are typically mixed with virgin materials like PP, PE, and PET. After reprocessing, these materials are used to manufacture new packaging materials, effectively promoting the recycling and reuse of waste plastics.

Single Material

With pp spring external configuration and PP environmental-friendly materials, the sixth-generation pump head is constructed and upgraded to a "single-material product", which can be recycled as a whole according to the plastic recycling standard of "5" PP category.

Refillable

By replacing the inner liner, the outer bottle can be reused, thus reducing the use of plastic.

Post-Consumer Recycled

After reducing plastic use and lowering carbon consumption, plastics are recycled and regenerated. They are typically mixed with raw materials such as PP, PE, and PET, then processed to manufacture new packaging materials, effectively promoting the recycling and reuse of waste plastics.

Compared to traditional plastics, PCR’s carbon emissions are only one-third. This is attributed to innovative process optimization, the use of renewable energy, and the continuous development of bio/recycled products.

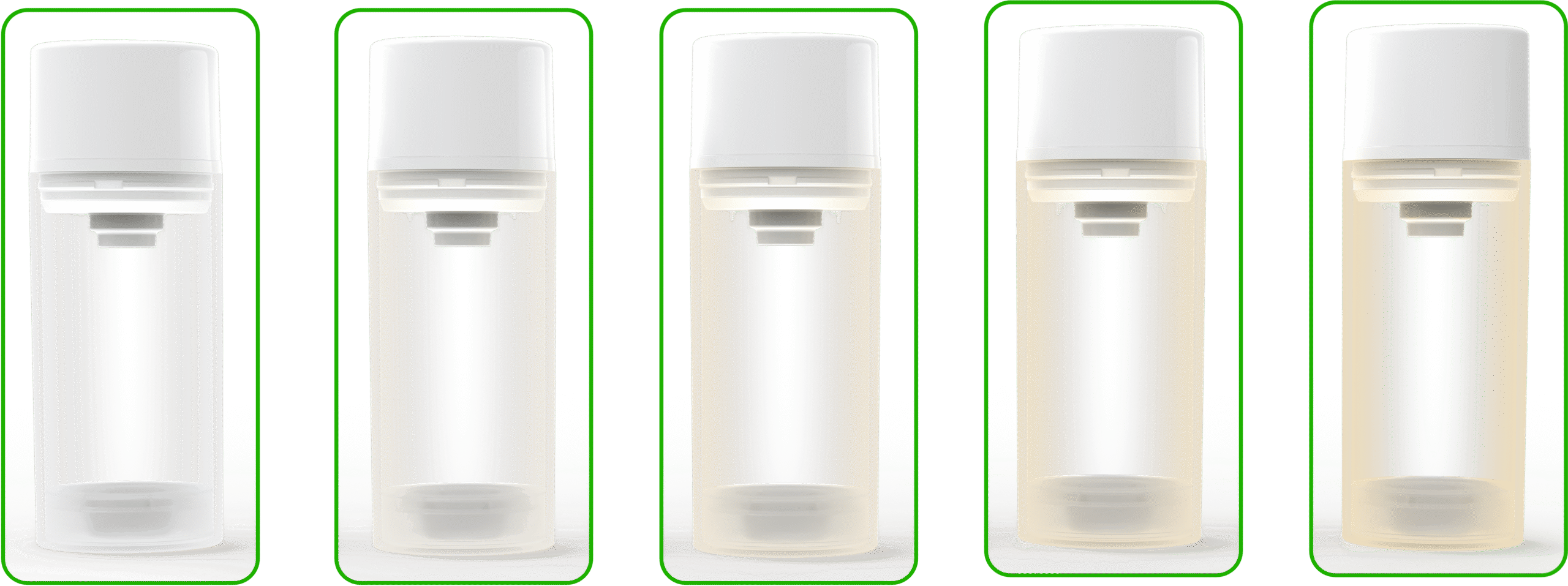

The effect of adding different proportions of PCR material:

10%

20%

30%

50%

100%

ALL PLASTIC COMPONENT.

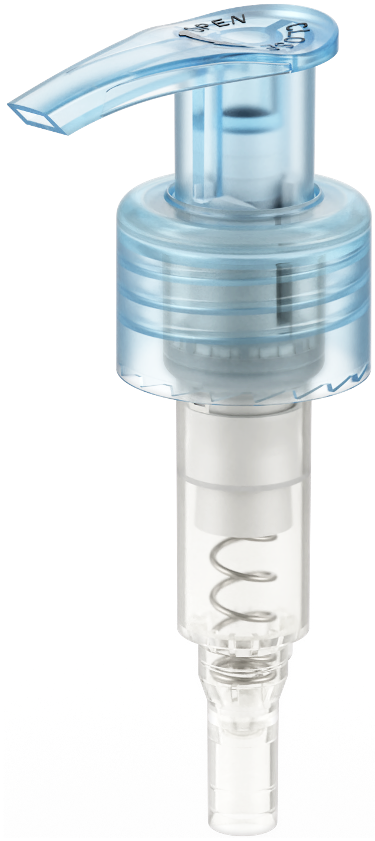

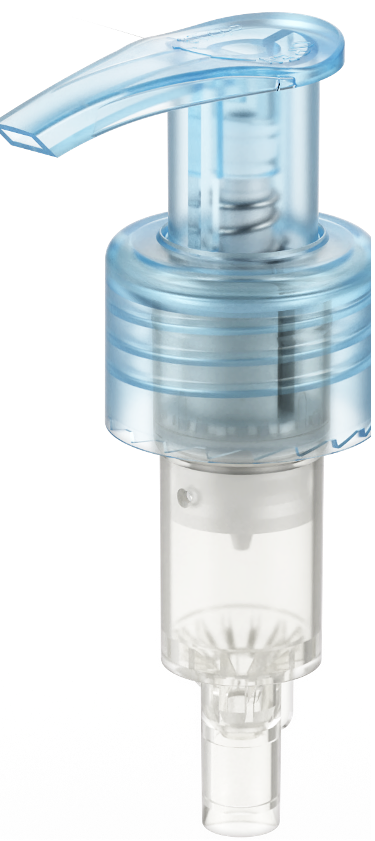

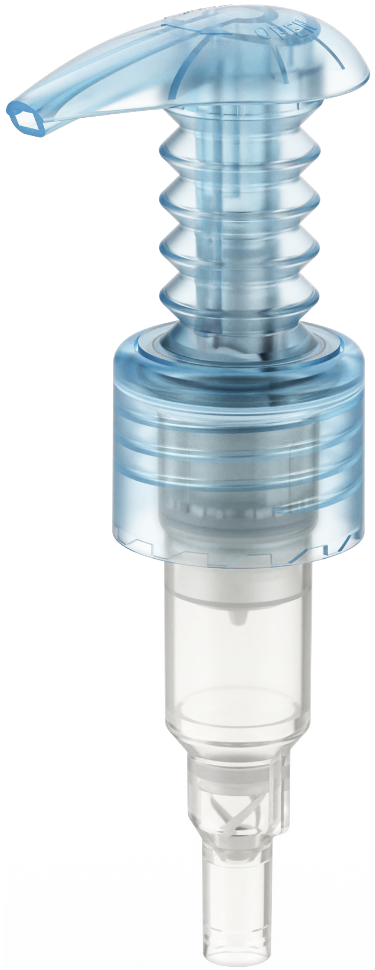

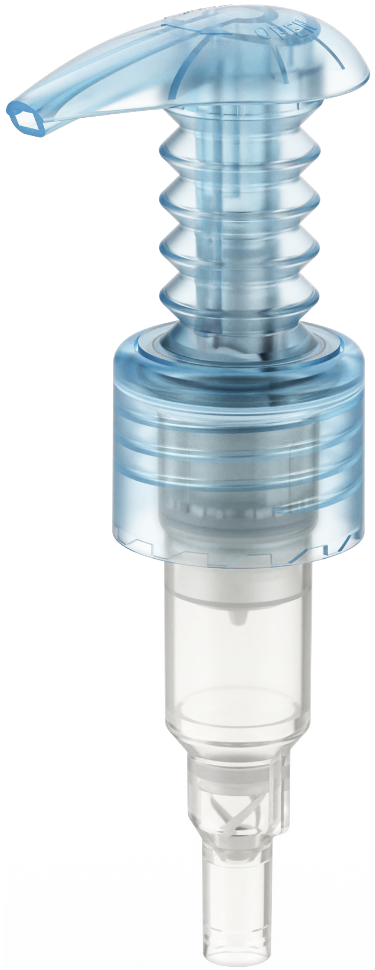

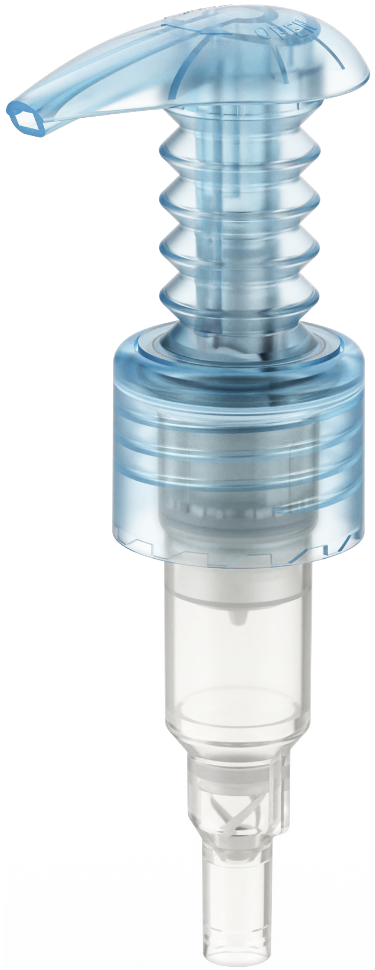

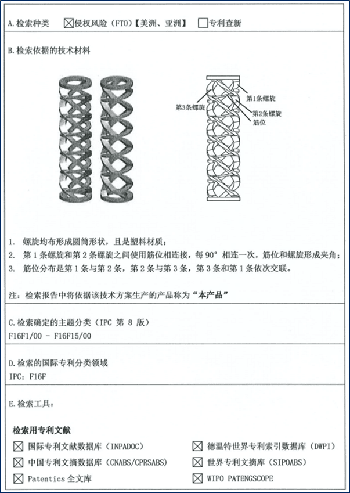

Development Of Plastic Pump Core.

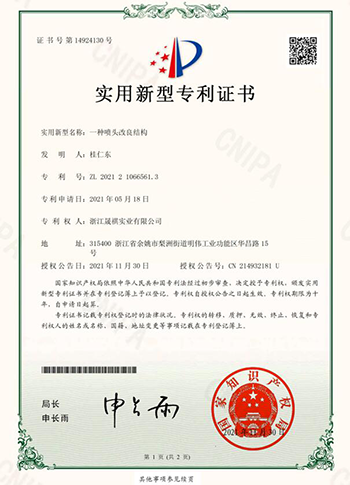

Chinese/Korean/EU Design Patents, Utility Model Patents, U.S. Authority APR Recyclability Certification, FTO Anti-Infringement Investigation Report.

2006

First Generation

The first generation of the original pump consists of inner metal spring and other accessories with POM, PP/PE materials.

2008

Second Generation

The second generation pump has been upgraded to the outer spring and POM material. The concept of "Zero contact between metal and liquid" is put forward.

2011

Third Generation

The third-generation pump is made of an outer metal spring and environmentally friendly materials PP and PE. The “POM-free” concept has been upgraded to eliminate consumers’ concerns about polyoxymethylene and to create eco-friendly packaging.

2015

Fourth Generation

The fourth-generation pump is made with an outer TPU spring and environmentally friendly materials PP and PE. It introduces the concepts of “demetallization” and an all-plastic pump.

2020

Fifth Generation

The fifth-generation pump consists of an outer TPE spring and all components made from PP+TPE eco-friendly materials, upgraded as a whole to meet plastic recycling standards.

2023

Sixth Generation

The sixth-generation pump consists of a PP outer spring and other parts made from PP eco-friendly material, upgraded to a mono-material design that can be fully recycled.

Certificates

Sun-Rain continuously develops new products that are clean, environmentally friendly, biodegradable, dust-free, non-toxic, harmless to the human body, and energy-free. These products ensure safety and reliability for medical, edible, and household uses, always focusing on the needs of our customers and consumers.

Patent Num: ZL 2021 2 1066561.3

Patent Num: NO 015007434-0001

QUESTIONS?

Whether you’re curious about features, a free trial, or even press, we’re here to answer any questions.